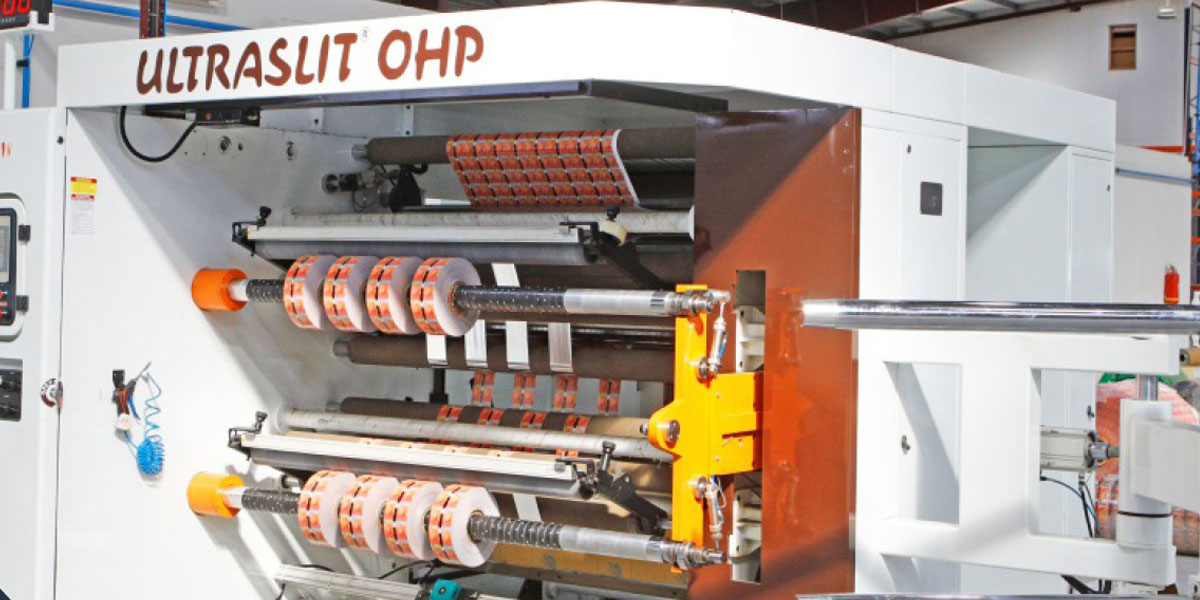

Our Slitting machine is engineered to handle a wide range of flexible materials from light weight films to medium weight paper, label stock and laminates with an operator friendly design. It also offers various options such as integral unwind reel stand, separate floor standing unwind reel stand, splice table, inspection table and overhead webpath. Our Slitting machine offers precise cutting accuracy and a high level of productivity. Apart from providing a hygienic work environment, the overhead path of the ULTRASLIT ® OHP Duplex Slitter Rewinder offers a hygienic work environment, easier web passage and allows larger reel diameters.

-

Shaft less unwind unit with or without the provision for floor lifting of reels.

-

Laser light indication for proper rewind core positioning during changeovers.

-

Razor in air, Razor in groove and Rotary shear slitting options.

-

Safety area scanner at unwind and rewind units as per CE regulations.

-

Shear cutting mode – tangential, for paper and aluminum foil based laminates

-

Shear cutting mode – tangential, for paper and aluminum foil based laminates

-

Electromechanical, linear floor lift for unwind reels

-

Splice table at unwind for registered joints

-

Rewinding on 152 mm/ 70 mm ID rewind cores

-

Motorized ejector for displacing the rewind reels on to the off loader

-

One touch off loader to transport the ejected reels to floor/ pallet level

-

Trim winding unit for the compact accumulation of trim waste

-

CCTV

-

SCADA

-

Increased diameter capabilities at unwind

-

Increased diameter capabilities at rewind